Understanding the Importance of Electrical Connectors

Electrical connectors are often underestimated when it comes to power systems, yet they play a vital role in ensuring system integrity, continuity, and most importantly, safety. Choosing the right connector isn't just about making a connection—it's about preventing fires, protecting equipment, and ensuring human safety. In any electrical installation, from complex industrial facilities to low-voltage residential setups, connectors act as the linchpins that hold the system together.

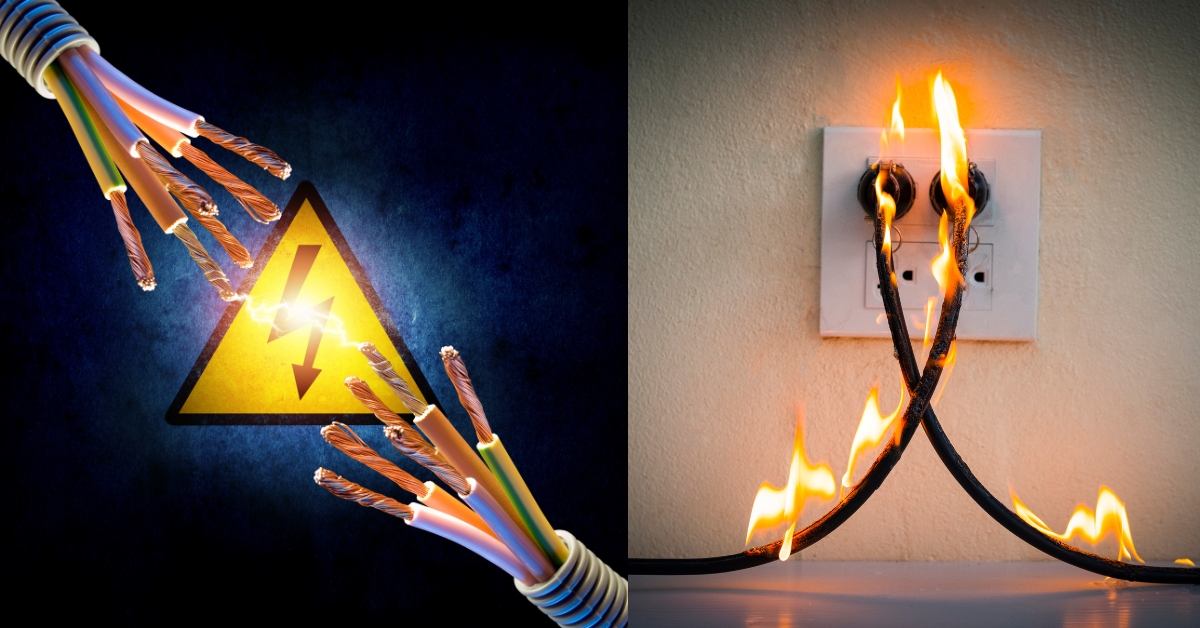

Risks of Poor Connector Selection

Improper or low-quality connectors can lead to overheating, arcing, corrosion, and even short circuits. These failures are among the top causes of electrical fires and system downtimes. A mismatched or substandard connector may not handle the current load efficiently, resulting in excessive heat generation and potential circuit damage. Loose fittings can also compromise insulation resistance and allow moisture ingress, increasing the risk of electric shock or component failure.

Connector Materials and Design: A Safety Backbone

The material and construction of electrical connectors greatly influence their safety performance. High-conductivity metals like copper and brass are commonly used for their superior current-carrying capacity and resistance to corrosion. Additionally, the insulation material must withstand high temperatures and environmental exposure. Modern connector designs now include locking mechanisms, moisture seals, and vibration-resistant structures to further boost safety in both indoor and outdoor environments.

Application-Specific Connector Selection

Different electrical applications require different connector specifications. For example, connectors used in Low Current System In India must be optimized for minimal voltage drop, precise signal transmission, and compact size. In contrast, connectors for high-power industrial systems must prioritize thermal management, current capacity, and mechanical strength. Understanding the application context is essential for selecting a connector that ensures safety and performance.

Role in System Compliance and Standards

Electrical safety is governed by national and international standards such as IEC, IS, and NEC codes. Connectors that meet these certifications offer a level of assurance in terms of safety, durability, and performance. Ensuring compliance with these standards not only reduces risks but also meets regulatory requirements, especially in commercial and industrial installations. When connectors adhere to standards, they support safe grounding, efficient bonding, and fault containment.

Maintenance and Monitoring of Connectors

Even the best-quality connectors require periodic inspection and maintenance. Over time, wear and tear, temperature fluctuations, or dust accumulation can degrade their performance. Regular maintenance ensures that connectors remain secure, corrosion-free, and functionally intact. Infrared thermography, torque testing, and continuity checks are effective tools for identifying potential issues before they become safety hazards.

Smart Connectors and Emerging Trends

With the advancement of smart grids and IoT-based systems, the future of electrical connectors is shifting toward intelligent monitoring. Smart connectors can now detect abnormal temperature rise, vibration, or moisture levels and send alerts in real-time. This evolution not only ensures predictive maintenance but also strengthens overall electrical safety by identifying faults before they escalate.

Trusted Partners for Electrical Safety

When dealing with electrical safety, selecting the right service provider is just as crucial as choosing the right connector. Working with the Top Electrical Solution Company in Rajasthan ensures that installations, maintenance, and upgrades are handled by experts who understand the intricacies of safe electrical infrastructure. Their knowledge, paired with high-quality components, forms a solid foundation for reliable and secure power systems.

Manikaran Enterprises: Commitment to Safety and Quality

Manikaran Enterprises has been a consistent leader in delivering high-performance electrical solutions across India. With a deep understanding of power system design, the company prioritizes safety in every component selection, including connectors. Whether it is a low-voltage residential system or a high-capacity industrial network, their teams ensure that each connection meets stringent safety and quality standards.

Conclusion

Connectors are more than just passive components—they are safety-critical elements in any electrical system. From preventing electrical faults to ensuring long-term system reliability, the right connector choice can mean the difference between a secure installation and a hazardous one. By understanding application requirements, adhering to standards, and working with experienced solution providers like Manikaran Enterprises, businesses and homeowners alike can secure their circuits and protect their assets for years to come.